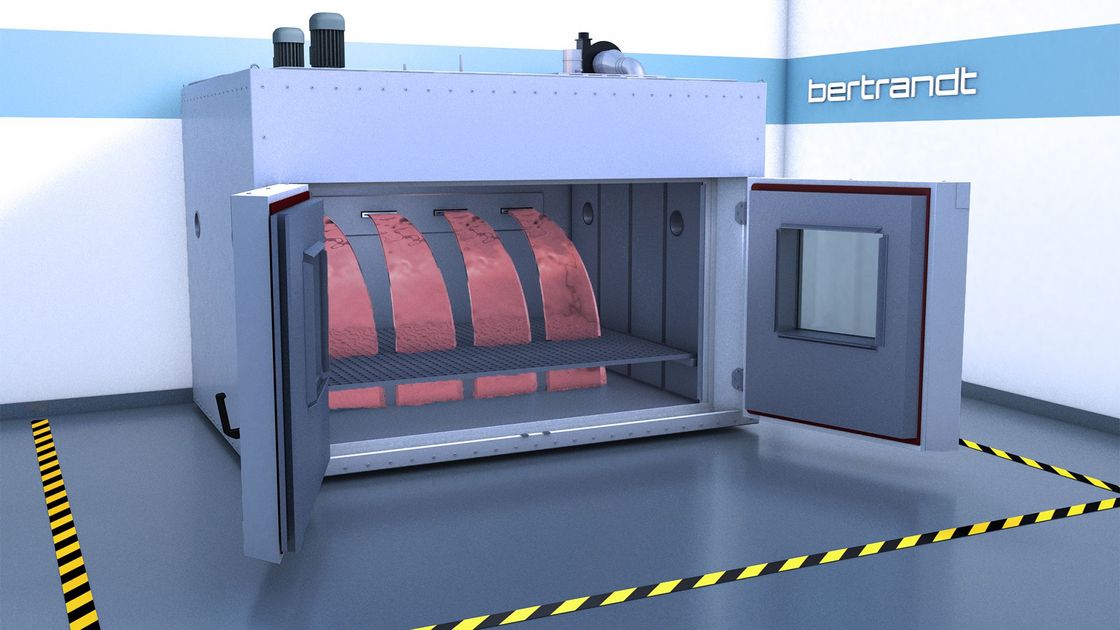

Vehicle components are exposed to a wide variety of electrical, mechanical, and chemical loads. Nowadays, it is not only about validating conventional electrical and electronic requirements, but also about dealing with new environmental influences in electric mobility. The components in electric vehicles are exposed to sudden changes in temperature if water splashes on them when the vehicle drives through puddles or pools of water. Bertrandt is now able to support its customers with a new splash water test chamber designed for large and heavy electronic components, thus allowing this process to be validated accordingly.

During the test, the vehicle component is first heated to its maximum operating temperature and is then shock-cooled with cold water at a temperature of 0 °C to 4 °C. Unlike conventional chambers, this new system has an extra large test chamber volume to allow even large components such as electric machines with a width of up to 1.8 m to be exposed to splashing water. As an additional feature, the chamber has a jet nozzle that can be placed in any position. “The new splash water test chamber helps us to examine electric mobility components under the most extreme conditions at an early stage in the development process, enabling us to detect any weaknesses and to reveal possible defects. Bertrandt has many years of experience and know-how in this field in both environmental simulation and electric mobility,” said Karl-Heinz Weinberger, Vice President Operations at Bertrandt. The chamber is designed to carry loads of up to 300 kg and meets all common automotive standards.

About Bertrandt

The Bertrandt Group is your leading solution partner for all technology trends. Our clear objective is to help shape the future of digital and electronic technology. In the automotive sector, we have combined our expertise across our different sites into four business units: Electronics, Product Engineering, Physical, and Production & After Sales. In addition, we provide support for customers in numerous other industries with our comprehensive know-how: from the energy and aerospace sectors to mechanical and plant engineering and medical technology. Around 12,000 employees at more than 50 sites are involved every day in successfully implementing our customers’ projects.